Thermal interface materials

Thermal interface materials

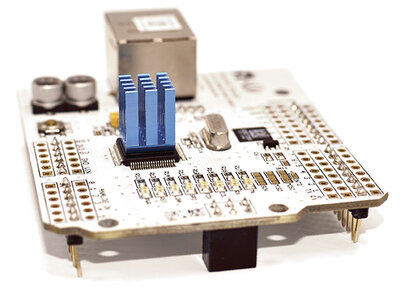

As you design your devices to be faster, smaller and more powerful, you need to protect their high powered electrical components from heat, which can lead to degraded performance and damage.

The range of silicone-based, thermally conductive interface tapes are designed to move heat more efficiently through the material, constantly cooling the component. You get maximum thermal management and excellent long-term performance under extended high temperature conditions.

Features and benefits:

• More efficient heat transfer due to low thermal resistance values of 0,37 to 0,64°C-in2/W

• Longterm durability (1000h) at 225°C

• Excellent wetting characteristics and provide uniform, thin bond lines

• WAsy to cut custom shapes and apply

• Available in single- or double-sided adhesive constructions, multiple thicknesses and with a choice of a polyimide or aluminium carrier film to meet a variety of applications and design needs

• Die-cut, mess free application

• UL94 V-O flame retardent

• REACH, RoHS compliant, halogen-free

• ESD-Safe™(DE-F1010, DE-F1012, DE-F1013)

| DE-F material number | Film | Silicone adhesive | Total thickness | Thermal resistance | Volume Resistivity | Temperature |

| DE-F1010 | 12,7 µm Polyimide | 40 µm double coated | 90 µm | 0,53°C-in2/W | 4 x 107 Ω /cm | 1,000 hrs at 225°C |

| DE-F1011 | 51 µm Aluminium | 40 µm doube coated | 130 µm | 0,37°C-in2/W | < 102 Ω | 1,000 hrs at 225°C |

| DE-F1012 | 38 µm Polyimide | 40 µm double coated | 110 µm | 0,49°C-in2/W | 7 x 106 Ω /cm | 1,000 hrs at 225°C |

| DE-F1013 | 38 µm Polyimide | 80 µm doubel coated | 190 µm | 0,64°C-in2/W | 4 x 1011 Ω /cm | 1,000 hrs at 225°C |

| DE-F1014 | 38 µm Polyimide | 40 µm single coated | 76 µm | 0,44°C-in2/W | 3,4 x 1011 Ω /cm | 1,000 hrs at 225°C |